Construction of biogas plant :

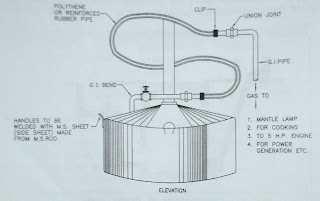

Biogas plant has following components.

1) Inlet tank

2) Disester

3) Gas space

4) Out let tank

5) Gas distribution system

(1) Inlet tank :-

The charging tank is kept for feeding the biomass such as cow dung, water, municipal wastes etc. The maximum of this biomass is prepared with water so that it properly flows by gravity and feed through his Inlet tank.

A screen or filter is provided on the inlet so that other unwanted materials do not enter the digester.

(2) Digester :-

It is cylindrical air tight well-type container made from steel tank or brick work masonry is nicely plastered to prevent any leakages. Size of the Digester depends on the capacity of the plan.

The biomass filled inside the digester must be for 30 to 50 days consumption.

(3) Outlet tank :-

The slurry or sludge from the biogas plant comes out through the out let tank from where it is removed manually. Outlet tank is also made up of brick work masonry.

The digested Biomass from from which biogas are produced is flowing out through this slurry out let tank. This slurry is now

No More capable to generate gas is removed from the biogas plant but it is very good fertilizer and it can be used in the farms.

(4) Gas distribution system :-

|

Gas distribution system |

It is made up of G.I. pipe , fitting, valves flexible pipes etc. It is Connected to the digester. The gas genenrate in the digester passes through the gas distribution system.

From where is it distributed for consumption. T- Drain is provided in the distribution system to remove the condensed water. Distribution system is also fitted with the manometer or pressure gauge to measure the pressure genenrated

The digester.

0 Comments